ONI-Wärmetrafo GmbH

Booth number: HALL 2.1 - G35

www.oni.de/

About us

Customers in more than 70 countries worldwide rely on our energy-saving and reliable plants and systems. From consulting and planning to turnkey plant construction and downstream service, we offer our customers all services from a single source. Today, our range of products and systems extends from small and medium-sized enterprises to global corporations. We owe the success of our company to a steadily growing customer base that successfully reduces energy and production costs with our systems, thereby improving its competitiveness. Our unique system expertise, comprehensive range of products and services, and outstanding corporate performance and innovative strength have contributed to our inclusion in the encyclopedia of German world market leaders.

In addition, we were included by German Standards in the publication “BEST OF GERMAN INDUSTRY,” which was published in December 2023 by the Zeit publishing group.

Address

Niederhabbach 17

51789 Lindlar

Germany

E-mail: info@oni.de

Phone: +49 2266 47480

Internet: www.oni.de/

No.329, Jujin Rd, Zhang Pu Town

215321 Kunshan City, Jiangsu Province

China

E-mail: info@oni-china.cn

Phone: +86 512 3662-5112

Internet: www.oni.de/standorte/

Christian-Bürkert-Straße 4

01900 Großröhrsdorf

Germany

E-mail: info@oni-rhytemper.de

Phone: +49 35952 4110-0

Internet: www.oni-rhytemper.de/

Contact person:

Guido Hamm

Sales Manager Asia-Pacific

E-mail: g.hamm@oni.de

Phone: +86 155 0613 0550

Products & Services

From individual project consulting to precise planning and design to professional construction, installation, and comprehensive customer service, we offer you all services from a single source.

Our product range:

Cooling/refrigeration systems

Heat recovery

Air conditioning/ventilation systems

Battery storage technology

Ice storage

Rental cooling systems

Clean room technology

Compact coolers

Dry coolers

Modular energy centers

Temperature control systems

Energy optimization

Water treatment

Compressor supply

Project planning

Round-the-clock maintenance/service

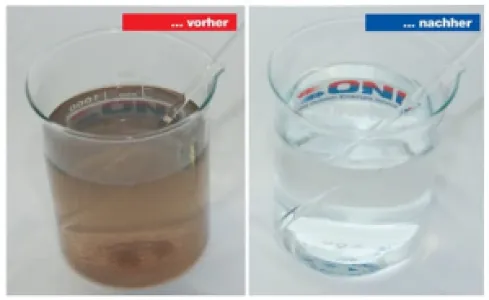

ONI-AquaClean Water Treatment

ONI-AquaClean – Top cooling water quality without biocides

ONI-AquaClean ensures consistently high cooling water quality without the use of biocides. The innovative system reliably reduces biological contaminants such as bacteria, algae, and fungi, as well as solid particles – from coarse to fine grains – in a single process.

Ozonation and ultrafiltration significantly improve water quality in a short time, reduce corrosiveness, and considerably lower the need for chemicals and maintenance. The result: higher energy efficiency, greater operational and process reliability, and lower operating costs.

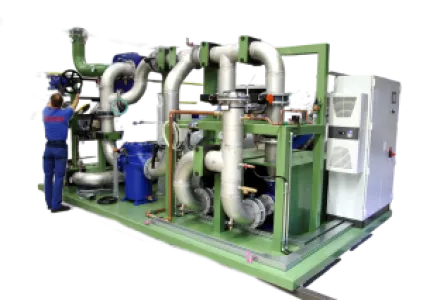

Efficient cooling systems for industrial applications

We plan, implement, and operate customized cooling and refrigeration systems for industrial processes. Our systems stand for high energy efficiency, maximum operational reliability, and durable plant technology. By using modern components, intelligent control technology, and holistic system concepts, we sustainably reduce energy consumption and operating costs.

Our solutions are individually tailored to the requirements of our customers and cover a power range from 5 to 150,000 kW – reliable, economical, and future-proof.

Needs-based and energy-efficient cleanroom systems

We plan and implement customized cleanroom systems for a wide range of industries—from plastics processing to pharmaceuticals, medicine, and food. Our services range from consulting and technical planning to complete ventilation equipment and turnkey, GMP-compliant handover.

Our modular cleanroom systems ensure maximum process and operational reliability with optimized energy and operating costs. Temperature, humidity, and particle concentration are reliably controlled – from compact FFU solutions to large-volume cleanrooms, including media supply and intelligent control and regulation technology.

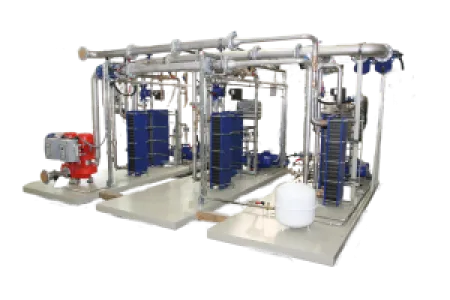

Heat recovery - saving energy through innovative technology

Our heat recovery systems use waste heat from industrial processes (e.g., compressed air, cooling water, hydraulics) to heat halls, offices, or break rooms – starting at just 35 °C.

This means that energy that has been paid for once can be used multiple times, significantly reducing energy costs and protecting the environment. In many cases, boilers and large heating systems can be completely replaced – the systems require little space and pay for themselves quickly, often even without equity capital through leasing.

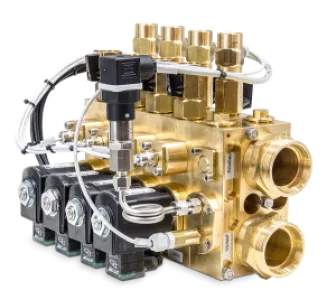

Rhytemper® temperature control system

Optimal temperature control management for maximum process stability

The unit costs for die casting and injection molding are largely determined by mold temperature control, as it directly influences process stability, product quality, and cycle time. Conventional flow-through temperature control systems often extend cycle time, do not offer quality monitoring, and do not reliably secure the process.

The Rhytemper® temperature control system, on the other hand, optimizes temperature control management specifically for the molded part. It records the thermal fingerprint of the part via the heat balances of the individual temperature control circuits and monitors it continuously during production.

By adjusting the temperature difference and volume flow, the thermal structure is kept constant – for stable processes, higher quality, and shorter cycle times.

On average, cycle time reductions of 18% are achieved, and in individual cases up to 40%.

-thumb.webp)