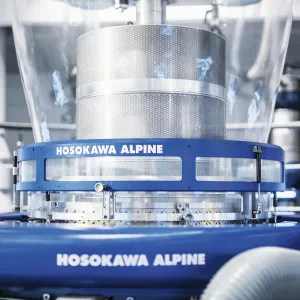

Hosokawa Alpine AG

Booth number: HALL 2.1 - F88

www.hosokawa-alpine.com/blown-film/

About us

Hosokawa Alpine AG is one of the world’s leaders in blown film technology. The more than 125-year-old German brand has made a name for itself with cutting-edge technology and the highest ‘Made in Germany’ quality standards. From 2015, Shanghai RongYan Trading Co., Ltd. became its exclusive distributor in Greater China. With its deep market understanding, Shanghai RongYan offers localized business and technical consultancy to help Chinese customers make the most of Hosokawa Alpine‘s firstrate technology.

Address

Peter-Dörfler-Str. 13-25

86199 Augsburg

Germany

E-mail: plastics@alpine.hosokawa.com

Phone: +49 8215 9060

Internet: www.hosokawa-alpine.com/blown-film/

Room 501, Longyang Center Tower No. 1990 Longyang Road Pudong

200127 Shanghai

China

E-mail: yantao@shronyan.com

Phone: +86 21 60738138

Contact person:

Christian Kistinger

Managing Director

E-mail: c.kistinger@alpine.hosokawa.co.th

Products & Services

Film Extrusion Lines for Blown Film, for mono layer and multi layer films with 3, 5, 7, 9 or 11 layers, MDO Film Orientation lines with unique TRIO systems - Film Winders.

7 / 9 Layer lines

Produce High-Barrier Films on Hosokawa Alpine machines! Multi-layer flexible packaging films are in demand around the globe and require speciality barrier extrusion lines. These products prevent the permeation of oxygen, nitrogen, carbon dioxide and water vapor. They also protect the aromas and flavors of the finished product. Produce on 7-, 9- or 11- layer lines – the more layers the more options for you to engineer and tailor your film products, while saving raw material costs.

Machine Direction Orientation MDO

Wether you want to produce full PE laminates, diaper bag sheets, laminating film or twist film this is the perfect solution. Less trim waste and improved film flatness for the MDO inline orientation process. The uniqueTRIO system optimizes the film thickness profile in-line. The result: minimum thickness variation across the entire layflat width. Additionally,edge trim is reduced by up to 50%, while the film flatness is greatly improved for converting.