B&B Verpackungstechnik GmbH

Booth number: HALL 2.1 - G61

www.bub-group.com

About us

At B&B Verpackungstechnik, we listen carefully and have a strong sense for our customers’ real needs. Only in this way can we develop machine solutions that are perfectly tailored to each application and offer maximum flexibility. Even special requests or custom solutions pose no challenge for us.

The foundation for today’s globally successful B&B Verpackungstechnik GmbH was laid in 1977 with the establishment of a mechanical engineering design office by Jost Bäumer. Alongside engineering services, the company soon began implementing its own ideas. Under the name B&B, the focus then shifted to the development and manufacture of pouch machines. With the acquisition of MAF Verpackungstechnik GmbH in 2004, the company expanded its expertise to include end-of-line packaging machines.

Today, more than 220 employees work on 16,000 square meters in Hopsten, Germany, and Green Bay, Wisconsin, USA, developing customized technical solutions for customers worldwide. As an owner-managed company, the main focus lies on the development of pouch machines and end-of-line packaging machines.

In addition to consistently high quality and a worldwide service promise, B&B Verpackungstechnik GmbH is characterized by long-serving employees, young creative minds, as well as flexibility and stability. Thanks to short decision-making paths, the company is always able to work flexibly and unconventionally on the implementation of customer-specific solutions. B&B Verpackungstechnik GmbH continues to rely on a healthy balance between innovation and tradition.

This is because only a broad base of experience combined with creative solution concepts enables the medium-sized company to continue its positive growth.

Address

Kupferstr. 18

48496 Hopsten

Germany

E-mail: mail@bub-group.com

Phone: +49 5458 7930

Internet: www.bub-group.com

Contact person:

Rafael Imberg

Head of Exports Asia / Middle East

E-mail: imberg@bub-group.com

Phone: +49 5458 793793 / +49 151 40728120

Products & Services

Bag making machines:

Side-gusseted plastic bag machines (SFB) – optimal packaging for dry products; current machines already process mono materials

Medical bag machine

Woven PP bag machines

Stand-up pouch machines

Packaging machines:

Packaging in Case

Packaging in Paper

Packaging in Film

Tissue

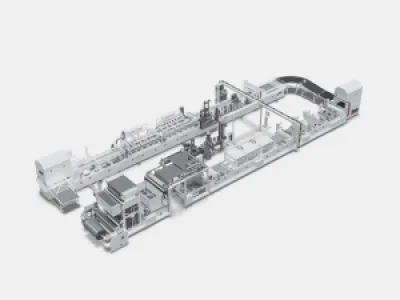

Side gusset bag making machine

Production capabilities

Max bag dimensions 1000 mm x 450 mm x 200 mm

60 – 80 cycles / min

2 up possible

Up to 1400 mm web width

Longitudinal production process (possible)

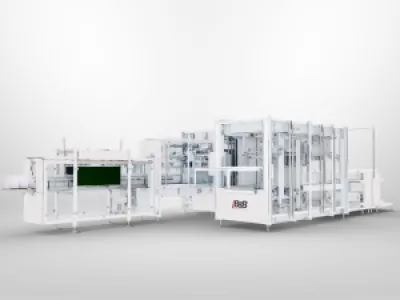

Stretch packer SBP

No need for a shrink tunnel -> less power consumption (high savings potential) and therefore less energy costs

Less film consumption compared to shrink film machines (savings of up to 80% possible)

Higher performance than comparable shrink packers

No influence of heating on the primary packaging

No more gluing with the primary packaging / no dimpling effect

Printed film can be used

Optimal dimensional stability of the product for easy and efficient palletization

Automatic splicing / roll change possible

Variable seam positioning

Easy open perforation

Sensitive, non-rigid products can be bundled to create a rigid package using a criss-cross banderole consisting of thin, highly stressable films; side overlappings are utilized to create a dustproof secondary packaging

Minor maintenance effort for the machine

Design in stainless steel possible

Unproblematic integration into packaging processes

Woven Bag Machine

The SFB – WPP is designed for the production of side gusseted woven PP pinch bottom bags. Working from flat film, up to 120 bags per minute can be produced. A wide variety of options can be integrated for different bag features.

The top or bottom closure can feature Hot Air Sealing Technology, the use of hot melt, tape or even sewn closures.

The BBR – WPP is also dedicated to the production of woven PP bags. Instead of starting from flat film, the machine is working from a roll of bag tubes and separates the bags individually.

Optional, both machine types can be combined with the Top Closure System TCS – WPP for inline Slider closure application.