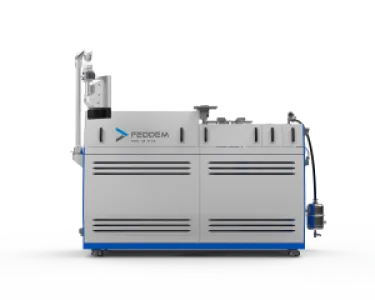

FEDDEM GmbH & Co. KG

Booth number: HALL 2.1 - J01

feddem.com/en

About us

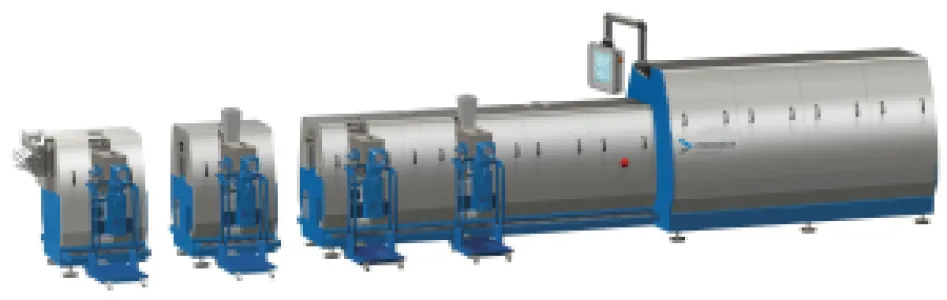

FEDDEM GmbH & Co. KG, based in Sinzig/Germany, is part of the internationally active Feddersen Group (Hamburg/Germany). With over 30 years of experience, FEDDEM develops co-rotating twin-screw extruders for high-performance technical plastics, with machine sizes from 18 to 82 mm and throughput ranges from 4 kg/h to 4 tons/h, designed to meet customers’ production needs.

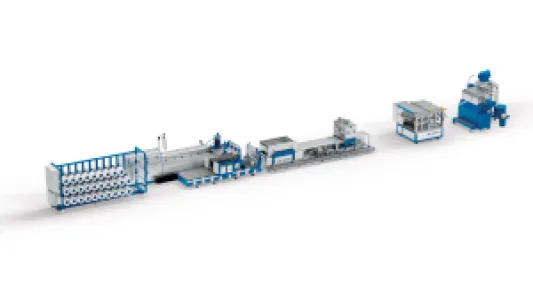

In addition to individual extruders, FEDDEM provides turnkey plants tailored to customers’ requirements, as well as LFT lines for producing Long Fiber Thermoplastic (LFT) compounds, helping customers achieve high-quality, consistent results.

FEDDEM supports customers with process optimization, customized solutions, and performance-enhancing products, along with a wide range of peripheral equipment to increase operational efficiency and reliability.

At the Technical Center, customers can conduct pilot trials, test new materials, and evaluate FEDDEM systems under production-relevant conditions, ensuring optimized processes before implementation.

FEDDEM technology is field-proven at AKRO-PLASTIC, one of Europe’s leading technical compound producers, with plants in Germany, China, and Brazil, giving customers confidence that the systems deliver reliable performance in real-world production.

Customers benefit from fast, flexible spare parts supply, tailored solutions, and comprehensive service, including remote support, so their plants maintain high availability and minimal downtime.

With FEDDEM, customers gain innovative, high-performance extrusion solutions and a full-scope service portfolio designed to maximize efficiency, reduce operational risks, and support innovation at every stage – from lab trials and pilot lines to turnkey production facilities worldwide.

Address

Mosaikweg 19

53489 Sinzig

Germany

E-mail: info@feddem.com

Phone: +49 2642 90781-30

Internet: feddem.com/en

Contact person:

Products & Services

Twin Screw Extruder

Turn-Key Plants

LFT Pultrusion Plant

Side Feeders and Side Venting/Degassing

Side Feeder Type FSB-V with Vacuum Support

FEDDEM Extension unit

FEDDEM Automatic AirBlade

Dual Cleaning Brush

Spare Parts

Service

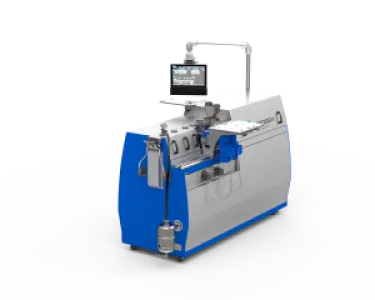

Twin Screw Extruder

Co-rotating twin-screw extruders for high-performance technical plastics, with machine sizes from 18 to 82 mm and throughput ranges from 4 kg/h to 4 tons/h, designed to meet customers’ production needs.

Turn-Key Plants

An identical production concept at every location worldwide means uniform production conditions, equivalent products and a minimum of spare parts stocking. Not only is it possible to reduce the costs, the ratio of quality to price is increased as well. The flexible systems used here adapt quickly and easily to changes in customer requirements. Sustainability and energy efficiency are a matter of course for us. FEDDEM has developed the standardised machine concept ICX® Technology (Innovative Compounding and Extrusion Technology) in partnership with its sister company AKRO-PLASTIC.

High-performance LFT Pultrusion Plant

Especially for the production of lighter functional parts for automotive applications, sports and leisure and the construction industry as well as for safety and functional equipment, the new generation of FEDDEM FLF PT pultrusion lines offer enormous advantages over conventional LFT compounding lines.

The special FEDDEM method not only halves changeover times when threading new rovings but also ensures tight tolerances in glass fibre content in the produced pellets. With FEDDEM’s ICX® Technology and its application to FLF PT turnkey lines, you can produce long fibre compounds based on engineering plastics more economically, more gently and with greater flexibility.

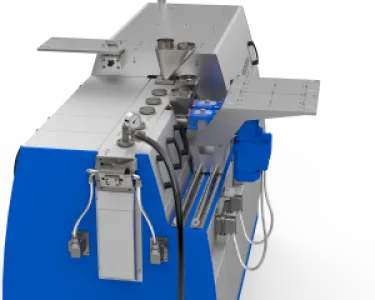

Side Feeders and Side Venting/Degassing

FEDDEM offers a range of auxiliary devices for ensuring smooth continuous performance of feed and degassing openings in the processing section. These devices are equipped with twin-screw discharges and frequency-controlled drives. Various speeds and screw pitches as well as a selection of metallurgies for abrasion and/or corrosion resistance allow to adapt these devices to individual process requirements.

Side Feeder Type FSB-V with Vacuum Support

To optimise the side streams in the compounding process, FEDDEM has developed a modified FSB side feeder, which sucks air out of the metered side stream before it enters the extruder. When adding materials with lighter bulk density, this enables a considerable increase in the throughput rate of the entire process. Compared to conventional side-feeding of low-bulk-density additives, the throughput of the compounding line could be increased several times over. In some applications, economically viable production rates only became feasible with the use of an FSB-V side feeder.

FEDDEM Extension unit

The FEDDEM Extension unit (e.g. 10 L/D long) allows for easy modification of an extruder´s length to match the requirements of an individual process. Changing the processing lengths just takes a few hours. This offers the option of adapting the processing length of an extruder from a compounding application to large-volume venting / degeassing or to reactive processing. Subsequent retrofitting of FEDDEM extruders to a longer processing length is an option and entails substaintially lower investment costs compared to sourcing an additional extruder.

FEDDEM Automatic AirBlade

Beard formation and product residues at the die outlet often pose a major challenge in the compounding of plastics.

This phenomenon, known as beard formation, occurs with a wide variety of polymer compounds. The FEDDEM Automatic AirBlade (FAA) reliably removes product residues, ensures seamless production and guarantees consistently high product quality.

The FAA is equipped with a powerful 2 kW blower that generates a focused airflow through the slit nozzle.

This airflow is heated to a preset temperature by a 9 kW heating element, enabling it to safely and effectively remove residues at the die exit by precisely blowing them away.

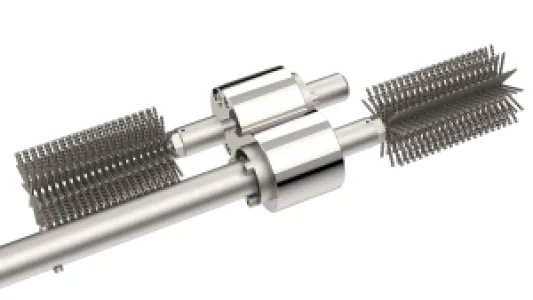

Dual Cleaning Brush

The principle of the FEDDEM dual brush assembly for cleaning has now proven itself in installations throughout Europe. The two brushes are driven centrally via a distribution gearbox and can be inserted into the figure-8-bore of the twin-screw extruder at operating temperature after the screws have been removed. This considerably reduces cooling and heating times of the extruder and minimises the downtime of the line during product changes. The distribution gear and the diameter of the brushes are matched to the centre-line distance and diameter of the figure-8-bore of the target extruder. Our dual brushes are currently available for extruder sizes from 43 to 93 mm.

Spare parts

Our warehouses are well stocked with key spare parts for a fast and flexible response to short-term requests. We also manufacture customised parts for your individual applications.

Service for Extruders and Compounding Lines

On-Site Service

Remote-Service

Remote-Service

Wear Measurements

Process Know-how and Consulting

Technical centre

Retrofitting & modernisation

_Kamera_Ansicht1-thumb.webp)