Zeppelin Systems GmbH

Booth number: HALL 2.1 - F82

www.zeppelin-systems.com

About us

Zeppelin Systems specializes in developing and manufacturing components and systems for handling high-quality bulk materials. They are used worldwide in the chemical, plastics, rubber and tire and Lithium industries, as well as the food sector. Zeppelin Systems provides all plant engineering services from a single source, from basic engineering through in-house production of components and control technology to final installation and a comprehensive after-sales service. In addition, the Quality Service division offers quality management services for the aerospace and automotive industries. In the test centers, customers can also test their formulas or perform trials that are designed for plant optimization.

Address

Graf-Zeppelin-Platz 1

88045 Friedrichshafen

Germany

E-mail: zentral.fn@zeppelin.com

Phone: +49 7541 20202

Internet: www.zeppelin-systems.com

Room 906 Golden Land Building

No. 32 Liangmaqiao Road

100016 Chaoyang District Beijing

China

E-mail: office@zeppelin-china.com

Phone: +86 10 6432 4859

Internet: www.zeppelin-systems.com/de/en/

No. 1058, Xingwen Road, Jiading

201815 District Shanghai

China

E-mail: office-shanghai@zeppelin-china.com

Phone: +86 21 6733 5553

Internet: www.zeppelin-systems.com/de/en/

Contact person:

Teresa He

Marketing Manager

E-mail: t.he@zeppelin-china.com

Products & Services

Zeppelin Conveying Technology

Zeppelin Conveying Technology: Where Invisible Efficiency Drives Visible Profit

Storage Silos from Zeppelin Systems

Silo manufacturing has a long-standing tradition at Zeppelin Systems. Even in the early 20th century, during the era of airship construction, aluminum containers were being expertly welded. This special know-how developed into the driving force behind the realignment of Zeppelin companies after the Second World War – and made Zeppelin Systems the world’s leading plant engineering company for the handling of high-quality bulk materials.

Depending on the requirements, storage capacity and installation location, we offer different types of silos in aluminum or stainless steel: bolted (Bolt-Tec), welded (Weld-Tec) or welded on-site (Panel-Tec).

Weighing and Dosing

Zeppelin Systems offers a wide range of weighing and dosing systems, from silo and day bin weighing to small-component dosing stations suitable for both batch and continuous dosing and conveying of granular as well as difficult-flowing powdered bulk materials and liquids. Our systems include both Loss-in-Weight (LiW) and Gain-in-Weight (GiW) processes and are used across various industries such as plastics, paints, chemicals and additives, battery compounds, rubber, tires, and food.

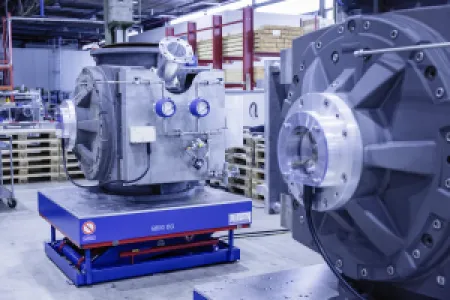

Zeppelin Components: Engineered for Uncompromising Reliability

As integral components of our total solutions, components from Zeppelin Systems are renowned for their precision engineering, enduring reliability, and exceptional performance. We not only deliver complete systems but also ensure every single component meets Zeppelin’s stringent original equipment standards. This makes them your dependable choice for system maintenance, upgrades, or customized integration.

Mixing Technology

Based on the pioneering HENSCHEL-Mixers® Zeppelin has been setting standards in the mixing technology for decades and has well-proven expertise in the areas of plastics, additives, colors, paints, pigments, toners, food, ceramics, minerals and metal compounds.

The new Container Mixer CMQ Specially designed for coloring applications, mainly Powder Coatings and Color Masterbatch, the CMQ provides highest flexibility and reduces cleaning time to a minimum. Integrated in an automated material handling system, Zeppelin offers a sophisticated process solution.