MAAG Germany GmbH

Booth number: HALL 2.1 - J61

www.maag.com

About us

The MAAG Group is a broadly diversified global solutions provider with integrated and customizable systems in process technology for the polymer, chemical and petrochemical. Its Pump & Filtration Systems, Pelletizing & Pulverizing Systems, Recycling Systems and Measurement & Control Systems divisions consolidate the many years of experience and in-depth know-how of the AMN, AUTOMATIK, ETTLINGER, GALA, MAAG, REDUCTION, SCHEER, SIKORA, WITTE and XANTEC product brands. The MAAG Group currently employs over 1,900 people at production sites in Switzerland, Germany, France, Italy, the USA, and China. Additional sales and service centers in Brazil, India, Japan, Korea, Malaysia, Mexico, Poland, Thailand, Turkey and United Arab Emirates, ensure close attention to customers’ needs. For more information visit www.maag.com.

The MAAG Group is a business unit of Pumps & Process Solutions, a segment of the Dover Corporation.

Address

Ostring 19

63762 Grossostheim

Germany

E-mail: info@maag.com

Phone: +49 6026 5030

Internet: www.maag.com

Contact person:

Aaron Kong

General Manager China

E-mail: aaron.kong@maag.com

Products & Services

The MAAG Group is a broadly diversified global solutions provider with integrated and customizable systems in process technology for the polymer, chemical and petrochemical. Its Pump & Filtration Systems, Pelletizing & Pulverizing Systems, Recycling Systems and Measurement & Control Systems divisions consolidate the many years of experience and in-depth know-how of the AMN, AUTOMATIK, ETTLINGER, GALA, MAAG, REDUCTION, SCHEER, SIKORA, WITTE and XANTEC product brands. The MAAG Group currently employs over 1,900 people at production sites in Switzerland, Germany, France, Italy, the USA, and China. Additional sales and service centers in Brazil, India, Japan, Korea, Malaysia, Mexico, Poland, Thailand, Turkey and United Arab Emirates, ensure close attention to customers’ needs. For more information visit www.maag.com.

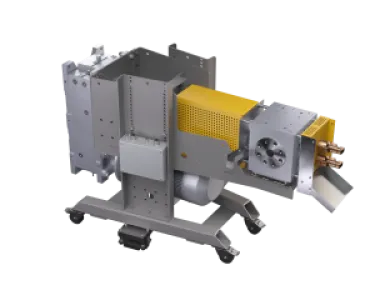

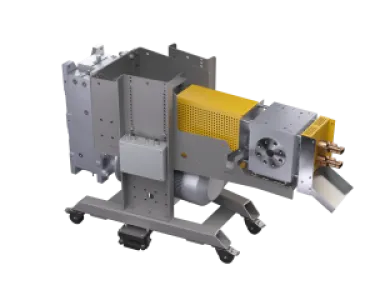

First gear pump specifically designed for pumping hard PVC

Extrusion operations require extremely reliable gear pump systems with high output consistency and a configuration to suit each application. The modular design of extrex® gear pumps easily meet the requirements for these diverse applications. The extrex6 EC gear pump is generally designed for PVC applications. The new pump design is optimized to the needs of processing PVC. All pumps are equipped with ST design (flow optimized). In addition, the process temperature is controlled by an innovative shaft cooling solution.

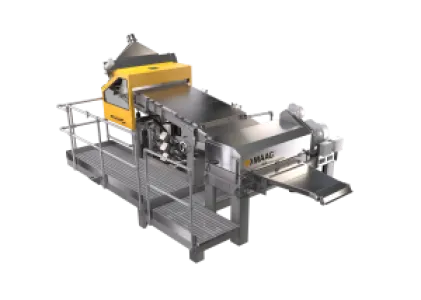

Maximum Process Stability and Pellet Quality for Next-Generation Production

With the new M²-USG generation, MAAG Group introduces a system that delivers enhanced process stability, increased throughput, and improved pellet quality—thanks to design upgrades and advanced sensor integration.

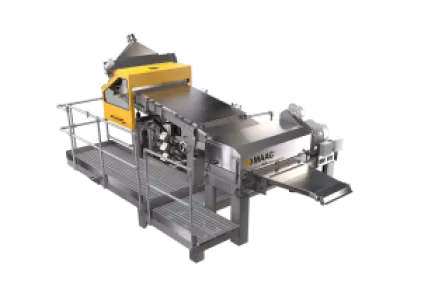

Revealing the secret of first-class pellets

The PEARLO 350 Underwater Pelletizer with EAC technology guarantees a precise blade adjustment for continuous operation, long lifetime of blade and die plate and a significantly reduced number of fines. The optimized water flow within the cutting chamber always ensures stable operation. Moreover, the die plate HTM design concept ensures open holes and a continuous A-Class pellet shape.

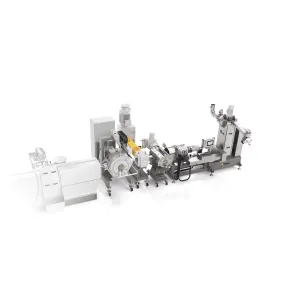

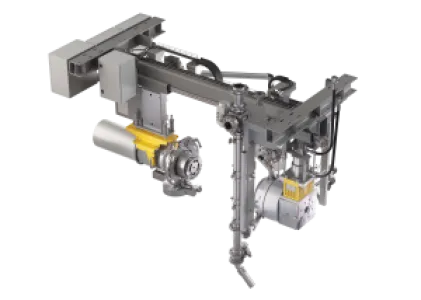

Newly developed double-stage melt filtration increases efficiency and recyclate quality

The combination of two high-performance melt filters offers operators the ability to continuously process even heavily contaminated plastic melts at high throughputs with fine filtration. The goal is to elevate the quality of recyclates to a level comparable to virgin material—while simultaneously optimizing plant efficiency.

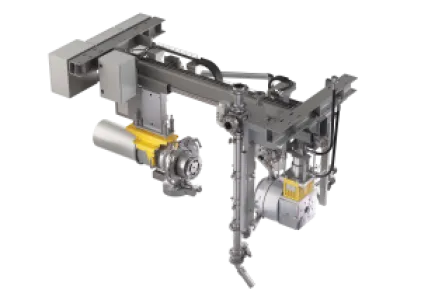

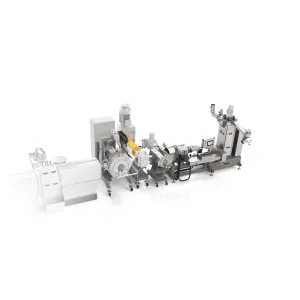

MAAG AMN Die Plate Unlocks Maximum Throughput and Quality

MAAG Group’s Central Injection System (CIS) — a game-changing innovation that redefines the pelletizing of high Melt Index (MI) polymers. Designed to tackle the most demanding production challenges, the MAAG CIS delivers unmatched performance, efficiency, and product quality for virgin polymer applications such as PE and PP; and is fully qualified for pelletizing high MI polymers ranging from 80 to 200.