Herbold Meckesheim GmbH

展位号: HALL 2.1 - F98

www.herbold.com

关于我们

赫博尔德梅克斯海姆是领先的回收技术专家,生产用于处理纯塑料废料以及废旧混合塑料和污染塑料的机械设备。该公司隶属于希伦布兰德公司,是科倍隆集团(www.coperion.com)回收业务部门的一部分,该部门提供完整的塑料回收解决方案。梅克斯海姆总部逾260名员工及国际分支机构团队,全程为定制化设备提供从概念设计、调试运行到商业使用终止的全周期服务。赫博尔德的产品线涵盖粉碎机、造粒机、研磨机及塑料压实机,尤其专精于洗涤分离系统——包含预分选、湿式粉碎、预洗装置、湿式造粒机、摩擦洗涤机、热洗涤与水力旋流器工序、机械及热干燥设备,以及水处理系统。所有组件与模块化系统解决方案均在公司自有技术中心完成测试。

地址

Industriestr. 33

74909 Meckesheim

Germany

电子邮件: herbold@herbold.com

电话: +49 6226 932-0

网址: www.herbold.com

联系人:

Mehmet Kaya

电子邮件: mehmet.kaya@herbold.com

展示产品

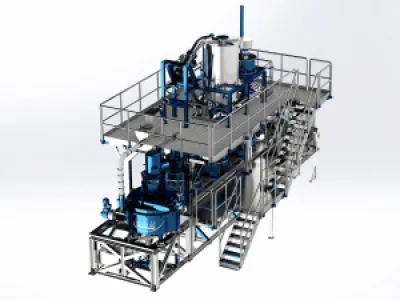

Washing Lines for Plastic Waste

We provide advanced machines and systems for washing, separation, and drying of used, contaminated, and mixed plastics. Our solutions transform waste—often pressed into bales—into clean, pure, and dry regrind or flakes, ready for densification, re-extrusion, or injection molding.

Our modular washing lines are carefully designed to progressively improve the quality of flakes at each stage, minimizing energy consumption and reducing fresh water usage. Whether you need a simple wet shredding setup or a comprehensive turnkey industrial washing line, we have the right solution for your needs.

The main areas of application for our washing lines are:

Agricultural films

Packaging films

Stretch films

PP tape bags (big-bags, raffia)

PET bottles

Bottles made of polyolefins

Fruit, vegetable and bottle crates

Hard plastics of all types

Plastics from car recycling

Waste from electrical devices (WEEE)

Containers and barrels

Old PVC windows

Battery cases

We understand service as more than just maintenance and repair. Rather, we dedicate ourselves daily to demonstrating our reliability, efficiency and expertise to give our customers a competitive edge in difficult markets.

We provide service and spare parts for these machines – also available at short notice. Knives, screen inserts, pulverizing discs, hammers, bearings, V-belts or conveyor belts – Herbold Meckesheim keeps a comprehensive stock of spare parts and wear parts. We also carry out overhauls and repairs – no matter whether your machine has broken down due to entry of a foreign body or by wear in long-term operation.

Our service technicians are available to work on-site on your premises. They install and commission the machines and systems supplied by us. They also support your personnel in the maintenance and repair of the machines.

Plastcompactor HV 70

The HV plastcompactor is a compactor for the densification of regrind of low bulk density, in particular shavings, foam, fibres and film – available in three sizes.

The agglomerate thus has a higher bulk density than the source material. It has good flow characteristics and can be extruded or injection-moulded without forced feeding. In mixing silos, e.g. after film washing lines, densified material gives higher amounts of material in a mixing batch, thus producing a more even mixture.

Mechanical Dryer T 2016 PA

Our latest innovation: the Mechanical Dryer T 150-300. It sets a new standard in modern drying technology with its completely new redesign for large-capacities reaching throughputs of up to 2.5 tons of film per hour.

The T 150-300 dryer is ideal for demanding industrial processes. Key features include a rotating sieve basket that performs full-coverage cleaning with integrated water spray nozzles, ensuring consistent surface cleanliness, and a centrifugal drying chamber that accelerates moisture removal efficiently.

The machine's construction allows easy maintenance, with hydraulically hinged housing for quick access, and advanced monitoring systems supporting predictive maintenance.

The T 150-300 is the ideal high-capacity dry cleaner, effectively removing fibers and particles.

Hydrocyclone Separation Stage

Unlike traditional swim-sink tanks, the Hydrocyclone Stage uses powerful centrifugal forces to achieve a precise separation of materials.

Exchangeable nozzle sizes allow fine-tuning for optimal results, while high turbulence and friction create an additional washing effect. Its advanced design thus not only improves the purity of recycled plastics, but also extends the lifespan of downstream equipment, reducing operational costs.

The Hydrocyclone adapts to various applications, delivering cleaner output and more efficient processing.

SMS Series Granulators – High-Performance Solutions for Demanding Applications

The SMS series comprises robust machines designed for challenging tasks such as size reduction of heavy lumps, tough fibers, ultra-thin films, or large material volumes.

Available as washing granulators, SMS models can process contaminated plastics by granulating them with water. The friction generated during this process ensures effective cleaning, combining washing and shredding into a single step.

We manufacture machines with working widths from 500 to 2000 millimeters and drive motors ranging from 22 to 250 kilowatts. The SMS series is ideal for recycling operations, offering versatility to smoothly switch between granulating high-volume hollow materials, thick-walled panels, or lumps—all with high performance.

Optionally, machines can be equipped with steel plating. Custom options include replaceable wear plates on top of the granulator, replaceable stator knife supports, and screwed, wear-resistant rotor knife support plates—all made from durable materials with the appropriate hardness and toughness to ensure long service life.