SIEMPELKAMP Size Reduction Solutions GmbH & Co.KG

Booth number: HALL 2.1 - F22

size-reduction.siempelkamp.com

About us

SIEMPELKAMP Size Reduction (formerly Pallmann) is part of the Siempelkamp-Group and one of the leading manufacturers of machines and complete systems for the preparation and size reduction of nearly all materials with the focus on the wood industry, the recycling of residual and waste materials, the plastics industry, the gentle preparation of foodstuffs, the pharmaceutical and the chemical industry. SIEMPELKAMP Size Reduction designs, manufactures and supplies tailor-made, individual or complete solutions for the processing of almost any plastic as well as recycling products. At its headquarters in Zweibrücken, SIEMPELKAMP company operates one of the world‘s largest research and development center for size reduction technology as well as a training and service center. A large number of test machines are available for the preparation of various raw materials including subsequent laboratory analysis on individual scale. In cooperation with the Siempelkamp group, SIEMPELKAMP Size Reduction has worldwide production facilities. Our global presence is ensured by a coordinated sales network for machinery as well as spare parts and after-sales service.

Our own service center secures the supply of wear parts and supports the customers in training their operating personnel. In case of a machine downtime or maintenance work, our experienced service technicians can quickly solve the problems at the site.

Address

Wolfslochstr. 51

66482 Zweibrücken

Germany

E-mail: management-srs@siempelkamp.com

Phone: +49 6332 802-0

Internet: size-reduction.siempelkamp.com

Contact person:

Michel Marchal

International Sales Director

E-mail: michel.marchal@siempelkamp.com

Jie Tang

Sales Manager

E-mail: jie.tang@extern.siempelkamp.com

Products & Services

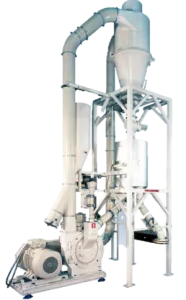

Pulverizing systems Agglomerators Disc Mills Knife mills Complete grinding systems Single- and double shaft shredder Universal mills.

100% utilization of plastics

During the production and processing of thermoplastics, production waste occurs. The Plast-Agglomerator processes this waste into free-flowing granules which are reused for production as valuable raw material.

Film- fiber- and foam waste is converted into free-flowing granules by means of the economical process.

Thermoplastic- as well as composite materials, dry or moist, can be continuously recycled with the same system.

This is performed with a minimum of thermo-degradable damage. The plastic granules are plastified by means of frictional heat to right below the melting point and thereby economically agglomerated.

Granulating plastics

Knife mills play an important role in the production and processing of plastics of any kind. The prepatation of production waste, reintroduced into new production, guarantees considerable cost savings. Resources are protected due to the preparation of already used plastics such as film-, bottle- and profile waste etc.

Due to the variety of materials, their form and constitutions, SRS supplies machine technology suited for the corresponding application.

Besides the many standardized applications, SRS Granulators are used for size reduction of heat-sensitive rubbers and elastomers, as well as for highly rigid fiber waste products. Furthermore, SRS Granulators are widely spread throughout the chemical- and recycling industry.

Experience the difference between fine grinding and grinding fine

Profitable pulverizing of thermoplastic material at ambient temperature is a job for experts. Different applications require special powder qualities with determined particle size distribution. The quality of powder flowability for rotomoulding for example, is specified in the German standard DIN 53492 and in the US-standard ASTM D 1895.