SIKORA GmbH

Booth number: HALL 2.1 - J61

sikora.net

About us

SIKORA, founded in 1973, celebrated its 50th anniversary in 2023. In 2025, SIKORA became part of the MAAG Group, a business unit of Dover Corporation (NYSE: DOV) within the Pumps & Process Solutions segment. Today, SIKORA is a leading global manufacturer and supplier of measurement and control technology, as well as inspection, analysis, and sorting systems for the wire and cable, hose, tube and pipe, optical fiber, and plastics industries. With more than 400 employees, 13 international subsidiaries, and over 30 regional representatives worldwide, the company delivers innovative product solutions and tailored service. All systems are engineered and manufactured at the headquarters in Bremen, Germany. Innovation, product quality, and customer satisfaction guide SIKORA’s daily work.

Address

Bruchweide 2

28307 Bremen

Germany

E-mail: sales@sikora.net

Phone: +49 421 489000

Internet: sikora.net

Software Road No. 89

Fuzhou Software Park, Zone C, Building No. 3, South Side of Floor 1

350003 Gulou District, Fuzhou, Fujian Province

China

E-mail: sales@sikora-china.com

Phone: +86 591 83361894

Internet: sikora.net

Office No. 112, First Floor, Rupa Solitaire Park, Millenium Business Park

400711 Mahape, Navi Mumbai

India

E-mail: sales@sikora-india.com

Phone: +91 22 49720177

Internet: sikora.net

Contact person:

Products & Services

Measuring and Control Technology for Hoses, Tubes and Plastic Sheets

Online Inspection and Sorting Systems for Plastic Pellets

Offline Inspection and Analysis Systems for Plastic Pellets

SIKORA CENTERWAVE 6000/250

SIKORA presents the CENTERWAVE 6000/250, for smaller tube diameters from 32 to 250 mm. It enables 100 % measurement of the wall thickness, as well as the determination of diameter and ovality for tubes with wall thicknesses from 1.6 mm due to its automatic adjustment of the rotation speed.

SIKORA X-RAY 6000 PRO

The X-RAY 6000 PRO is a powerful system to constantly monitor the wall thickness of single- and multi-layer products and to reduce it to the minimum tolerance value. Safety margins can be successively reduced, and the automatic control keeps the dimensions within the specification. The assurance of quality in combination with material savings leads to a significant increase in productivity.

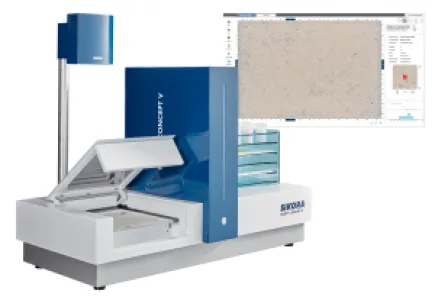

SIKORA PURITY CONCEPT V

For random sample inspection of plastic pellets or test plates for speck analysis, SIKORA presents the PURITY CONCEPT V. Within a few seconds, the test material is inspected for metal contamination or optical deviations. Contaminants are automatically detected, visualized and statistically evaluated. Visitors can bring small quantities of their pellets directly to the booth for testing and evaluation.

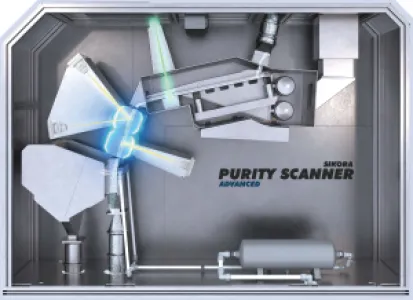

SIKORA PURITY SCANNER ADVANCED

SIKORA's PURITY SCANNER ADVANCED inspects 100 % of plastic pellets online and automatically sorts out contaminated individual pellets from 25 µm upwards. The system combines X-ray technology with a flexible optical system. In addition to the X-ray camera, up to three cameras can be installed depending on the expected contamination and application. All types of pellets are reliably inspected. The X-ray camera detects metallic impurities in the pellet and on its surface. Color deviations in transparent or on translucent and colored raw materials are detected by the optical cameras. Contamination are automatically sorted out, thus ensuring material quality.