SONOTRONIC GmbH

Booth number: HALL 2.1 - F18

www.sonotronic.de

About us

As a pioneer in the Ultrasonic Technology, SONOTRONIC GmbH develops and produces machines, systems and components for the joining of plastics. Our innovative systems are used worldwide by well-known OEMs to produce plastic parts for exterior and interior trim in the automotive industry. In addition, we manufacture high-tech ultrasonic systems for the plastics, packaging, food, textile, medical and environmental industries. With our Global Headquarters in Germany and locations in the USA, China and Spain, we are one of the leading companies in our industry. Together with our dedicated team, we are actively committed to ensuring a sustainable and forward-looking plastics joining technology.

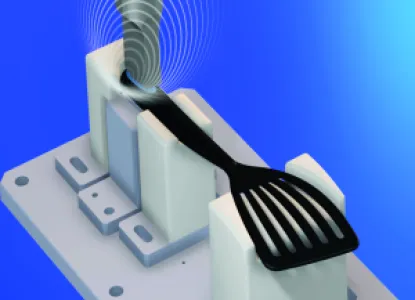

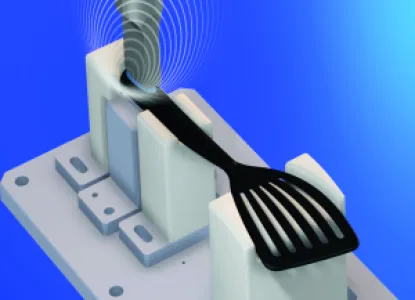

Caption: Series premiere of the iSONIC ECO™: The fully electric ultrasonic benchtop machine operates completely without compressed air, is maintenance-free, and particularly energy-efficient. With two integrated frequencies (20 kHz and 35 kHz) and an innovative quick-change system, it covers a wide application range – from welding to embossing to demanding areas such as medical technology. New: a 9.3'' display, optionally as a touchscreen.

The iSONIC ECO HSG handheld welding machine is versatile and enables efficient and flexible ultrasonic welding – anywhere, anytime. It is ideal for small-scale production as well as for repairs and finishing of thermoplastic materials. Various welding tasks such as spot welding, riveting, and cutting can be quickly and reliably performed with the ultrasonic handheld welding machine.

Specialist in ultrasonic welding of plastics. Application-specific solutions for joining and separating injection molded and extruded plastic parts using ultrasonic. Building standard and special machines, based on ultrasonic, hot plate, infrared and hot air technology. More than 50 years of experience in plastics joining and roughly 200 tailor-made special maschines per year worldwide.

Address

Becker-Göring-Straße, 17-25

76307 Karlsbad

Germany

E-mail: messe@asonotronic.de

Phone: +49 7248 9166268

Internet: www.sonotronic.de

10F Shensi Mansion, No.263 Shitai Road, Baoshan District

200444 Shanghai

China

E-mail: yangjm@sonotronic.cn

Phone: +86 13 764392673

Contact person:

Jim Yang 杨建明

Sales Director

E-mail: yangjm@sonotronic.cn

Phone: +86 137 64392673

Products & Services

Sustainable plastics processing

■ Ultrasonic welding

■ Ultrasonic cut & seal

■ Ultrasonic roll seam welding

■ Ultrasonic cutting

■ Ultrasonic punching

■ Ultrasonic riveting

■ Ultrasonic embossing

■ Ultrasonic thermofixing

■ Ultrasonic washing

■ Ultrasonic disintegration

Products

■ Special machines

■ Standard machines

■ Ultrasonic systems

■ Ultrasonic components

Industry solutions

■ Automotive

■ Plastics

■ Packaging & Food

■ Technical Textiles

■ Environmental

Two frequencies. One machine. Countless applications Ultrasonic technology rethought: iSONIC ECO TM

The iSONIC ECO TM combines everything that modern production processes require: a compact, modular design combined with a powerful, purely electric stepper drive - completely without compressed air.This makes it maintenance- free, cost-efficient and particularly environmentally friendly. Two integrated frequencies and innovative interchangeable holders offer a wide range of possible applications - whether welding, punching, embossing or riveting. Ideal for the automotive industry, plastics processing, technical textiles and the packaging and food industries.

Series premiere of the iSONIC ECO™: The fully electric ultrasonic benchtop machine operates completely without compressed air, is maintenance-free, and particularly energy-efficient. With two integrated frequencies (20 kHz and 35 kHz) and an innovative quick-change system, it covers a wide application range – from welding to embossing to demanding areas such as medical technology. New: a 9.3'' display, optionally as a touchscreen.

iSONIC PULSE GEN B Digital ultrasonic generators

The digital ultrasonic generators of the iSONIC PULSE GEN B series bring many other advantages in addition to fast and precise control of the process.

Advantages

Software-supported commissioning by the ultrasonic Diagnostic System (UDS).

Data collection and transfer through Profinet interface.

Integration into the machine control unit through the Profinet interface.

Optional remote access via router on the machine side and UDS to the generator possible.

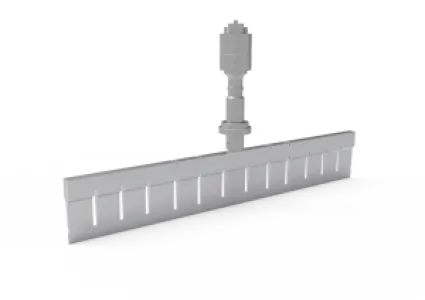

Precise cutting with ultrasonic technology by SONOTRONIC

Ultrasonic technology by SONOTRONIC enables cutting and separation processes for various products in the food industry to be automated. The units and systems can be easily integrated into existing machine concepts. Special tools (sonotrodes), which are made to oscillate by ultrasound, cut the particular product into pieces. As a result of the oscillation and the optional coating, the nonstick characteristics of the cutting sonotrodes are especially good. Cutting with ultrasound makes it possible to cut both very soft and very hard products efficiently.

Ultrasonic cutting sonotrodes:The sonotrodes conduct the ultrasonic oscillation into the workpiece and are individually tailored to size according to the application. Shape and contour can be adapted to your requirements. The development and production is based on the finite element method (FEM), which ensures optimum ultrasonic processing of the applications. SONOTRONIC offers cutting sonotrodes with a blade length of up to 750 mm and a cutting height of up to 170 mm.

iSONIC WAVE BRM Ultrasonic roll seam technology for technical textiles

Ultrasonic roll seam module supported at both ends

Continuous ultrasonic cutting and sealing

The ultrasonic roll seam units from SONOTRONIC are suitable not only for continuous sealing but also for the simultaneous cutting and sealing of synthetic textiles.

Continuous sealing seams with high design flexibility

In ultrasonic roll seam sealing, continuous sealing seams are produced by the disc-shaped sonotrode without seam interruptions, for which purpose the roll seam sonotrode has a titanium mounting on both sides. At the same time the design of the anvil wheels with different contours and widths allows flexibility in seam design.

Simultaneous cutting and sealing (Cut & Seal)

A further application of the innovative ultrasonic roll seam technology from SONOTRONIC is the simultaneous cutting and sealing of thermoplastic textiles with extremely wear-resistant steel sonotrodes. This produces not only fixed seams but also minimal seam projections. During ultrasonic edge cutting the edges are already sealed so that they cannot fray.

Possible applications In the textile industry ultrasonic roll seam units replace conventional sewing machines. Continuous sealing seams and seams with free geometries can be produced. Fabrics from thermoplastic synthetic fibres are then no longer sewn with one thread but are sealed ultrasonically, and because of this no holes are made in the fabric by needle stitches and there is no subsequent taping. Besides their use at manual workstations, ultrasonic roll seam systems can also be integrated in existing machines.

iSONIC WAVE ERM Ultrasonic roll seam technology for Packaging & Food

Roll seam module with cantilevered sonotrode

Ultrasonic sealing without heat loading of the filling material

An ever expanding application for the continuous ultrasonic sealing method from SONOTRONIC lies in packaging technology.

Applications

Here ultrasonic roll seam technology is applied mainly in horizontal and vertical tubular bag machines. Bags with four sealed edges can also be produced by ultrasonic roll seam sealing.

New possibilities in the choice of film

In addition, unlike other thermal processes, ultrasonic technology makes it possible to use monofilms, since no heat-insensitive outer layer needs to be laminated onto the film. Furthermore, even very thin polymer films (15 μm) can be sealed in high quality with the continuous ultrasonic process, which has not been possible satisfactorily with other thermal sealing systems so far.